The other day my husband came home and announced “You have a present from [our friend] Tim! He thought you could use it in your quilting!”

It was a whole bag of spools.

Lovely metallic thread?

Well, not quite. It’s actually copper wire. Specifically, it’s XBT wire, which stands for “eXpendable BathyThermograph.”

An expendable bathythermograph is sent down into the ocean to measure the temperature and how it changes from the surface down to the deep, something that both oceanographers and navies are very interested in. (It’s actually not oceanographers’ favorite way of measuring temperature, but this particular device can be useful when it’s too dangerous or not practical to lower and pull back up larger equipment, because it doesn’t have to be retrieved.)

Our friend Tim was on a research cruise and the ship was going to throw all these spools out, so rather than waste it all he thought I might be able to use it as thread. It’s thinner than a 12-weight thread—my guess is closer to 30-weight.

I was eager to try sewing with it. So I peeled off the bottom label to put it on the spool pin, and.. OH, HELLO GOO!

It felt like wax to the touch. It seemed possible that the wire was coated with this too. Not a great sign.

I googled it. No specifications to be found, so I emailed Tim. He didn’t know either.

I emailed Lockheed Martin/Sippican customer service.

Predictably, they ignored me since I mentioned I was an artist who already had their product, and clearly wasn’t going to buy anything from them.

Tim, though, was intrigued. Since the concern was the heat of friction melting the coating off the thread, he got out some heating equipment in his lab and heated it up. He wasn’t able to get anything off the wire, so he concluded it probably wouldn’t melt and gum up the machine.

The other question was whether the copper metal itself might damage the tension disks.

So I called HandiQuilter.

“Hello, I was wondering if your tension disks are made of stainless steel [which is harder than copper]?”

“Uhhhhhh, I don’t think so.”

“Oh, okay, do you know what they’re made of then?”

“Some sort of alloy I think.”

“But you don’t know what kind.”

“Uhhhhh, no.”

“Erm, okay, well, I wanted to try sewing with some copper wire and I wanted to make sure I wouldn’t damage anything.”

[pause]

“You’re probably fine.”

I’m pretty sure they thought I was crazy, but with that I decided to go ahead and try it. I was still thinking there was a hole in the bottom of the spool that I just had to dig out, so I got a plastic spoon and removed some goo.

I didn’t uncover a hole, but I did find some electronics!

Then I realized that there was a hole on the other end of the spool, so I decided to just flip the spool upside down and start threading the machine.

Of course, since it wasn’t designed to be used that way, the base of the spool caused the wire to hang up on it. When you’re using thread, it just breaks. I really didn’t want to find out what was going to happen here, so it was back to using it right-side up.

Painter’s tape to the rescue!

I was finally able to thread the machine and try stitching with it! Here’s what happened.

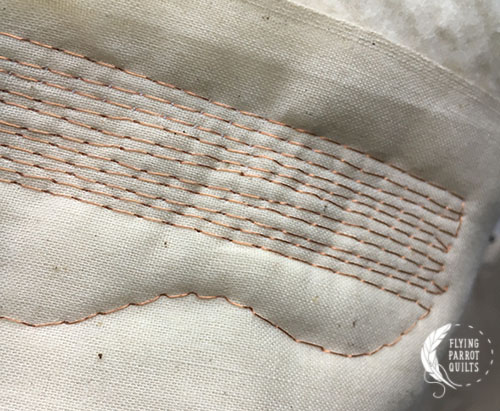

Both when free-motion quilting and when using the channel locks for straight lines, it made this loopy texture, regardless of the top tension.

I decided to try it in my domestic machine, too. It wasn’t my first choice, since on the longarm all the threading is on the outside, so it could easily be cleaned up if some goo did get into it, but the results here were markedly different!

When I tried free-motion quilting on the domestic, I got the same loopy texture, so it seems that it really needs the feed dog motion to keep the wire laying flat, but I actually kind of like the loopy texture and think it could make for an interesting effect next to the flat stitching on the right quilt.

So, overall I’d say it was promising. Now I have to think of the right project to use it on!

I’ve actually used XBT’s, way back in my sordid oceanographic past… Fun times.

So many things I love about this! Excellent use of XBT!

How about using a big stitch by hand to add dimension and color to a piece? Or maybe try weaving it and tacking it down with embroidery stitches.

I love what ifs? The wire would probably be great for beading. I did some beading using the copper wire taken out of a lamp cord I had cut off to replace.

you are braver than I am!! 🙂 I probably would have just put it on a shelf and looked at it for a long time. Or maybe tried to use in in something with beads for jewelry. Haha! HOpe you have a great bit if inspiration and have fun with it! Hugs, H

I have an artist friend who uses copper wire in her installations. sometimes she does tiny “thread” and ribbon paintings, sometimes she does huge 6′ by 4′ paintings with wires, ribbons, threads, pieces of wood & other elements.

If you have any spare copper wire I could send you her contact info.

I will try to send you a photo of a piece she once gave me as a birthday gift.

So when my thread isn’t seated in the tension discs of my longarm correctly, the top thread will look like that. Which makes me wonder if the copper is popping out of the longarm tension discs. I have an APQS, but my tension discs are exposed on the side of the machine, and I’d be tempted to experiment with plastic or something that might not gall/rub the same metal to metal kind of way. Regardless, a super cool experiment and I look forward to seeing how you use it!

I’ll be the geek that comments on the goo.:) So, electronics are not hardy when it comes to enduring the elements. Salt water can be extremely corrosive and make electronics nonfunctional. Potting, a more formal name for the goo, protects electronics and provides heat dissipation.

I love how you were undaunted, researched the coating, and improvised with painter’s tape. True grit.

Looking forward to see how you use this “thread” in your work. The domestic machine stitching appeals to me.

…..only a scientist!!!!

You are a true Artist. Willing to go to Great Lengths for your craft, and a new method. KUDOS to you!

Quite an adventure! Hope it works out for you. I like Mary’s idea about hand quilting, of course that depends perhaps on the extent of the quilting you are going to do. 🙂

This is so, so cool. I love that you are experimenting and can’t wait to see how you decide to use it! I also like the idea of hand quilting — I’m guessing if it works in a sewing machine then it must be fairly pliable?

Yep, weird threads are out there. Your Tension disks in the Avanti are probably steel (or more likely and iron alloy… a magnet would tell the tale there. But they are pretty expendable… ie: cheap to replace. What did you put in the bobbin? Regular thread? Tension is that battle between the thread in the top and the thread in the bobbin. Those disks squeeze that thread, pulling up the bobbin thread. Usually, we want to see those thread meet (lock) in the middle of the fabric… FYI, Superior Threads sells a stainless steel thread that can be used in the bobbin to create a circuit to light LED lights in your costume! A small battery box has to be hand sewn to the battery box to complete the circuit and power it. My maritime husband says the “goo” was likely to protect the copper from salt water, which can create electrolysis between “dissimilar metals”… so copper would dissolve if it touched the other metals used in the little electronics…salt water is very corrosive – even the salt in the atmosphere when you are on the ocean or near it… ever had a car near salt water – it’ll rust like crazy if kept outdoors! Copper FYI, is a very soft metal! So, won’t harm your machine’s guides or such unless used for a very long time! It all looked like fun to me!

How about couching this copper thread using a couching foot on your domestic machine? it would make for some awesome embellishment.

That is paraffin wax and the wire is not coated with it. The wax is used to cover the connection terminals so they will not rust while out at sea. Also on a deep blue probe that is twined wire not single strand wire.